Nano Heat Transfer Fluid

Benefits

Immediate Results: Experience a rapid improvement in energy efficiency and reduced operational costs as Maxwell™ starts optimising heat transfer right away.

Carbon Emission Reduction: By increasing thermal conductivity, Maxwell™ helps lower energy consumption, subsequently reducing carbon emissions and promoting environmental sustainability.

Cost Savings: Achieve significant energy cost savings and a rapid return on investment, with payback typically realised within 1 to 3 years, depending on usage rates.

Maxwell™ heat transfer fluid is not just a solution; it’s an innovation that paves the way for a more energy-efficient and sustainable future in cooling applications. Make the smart choice for your systems; choose Maxwell™.

Maxwell Heat Transfer Fluid is an advanced nanofluid technology that harnesses the power of microscopic particles suspended in a base fluid to significantly enhance heat transfer capabilities. Experience improved system performance and reduced energy consumption, leading to substantial cost savings. Maxwell heat transfer fluid, the game-changing nanofluid additive. Boost your heat transfer by up to 15%, slash energy costs, and reduce carbon emissions. It’s a drop-in solution, no retrofits needed. Transform your hydronic systems with Maxwell and experience immediate, long-lasting results. Your efficient future starts here.

Features:

Proven savings up to 15% – Increase in Thermal Energy Transfer: Maxwell™’s patented nanofluid technology significantly enhances the heat transfer capabilities of conventional systems, ensuring superior efficiency.

Easy Integration: A simple drop-in additive, Maxwell™ requires no retrofitting of existing systems. It seamlessly enhances performance without causing disruption.

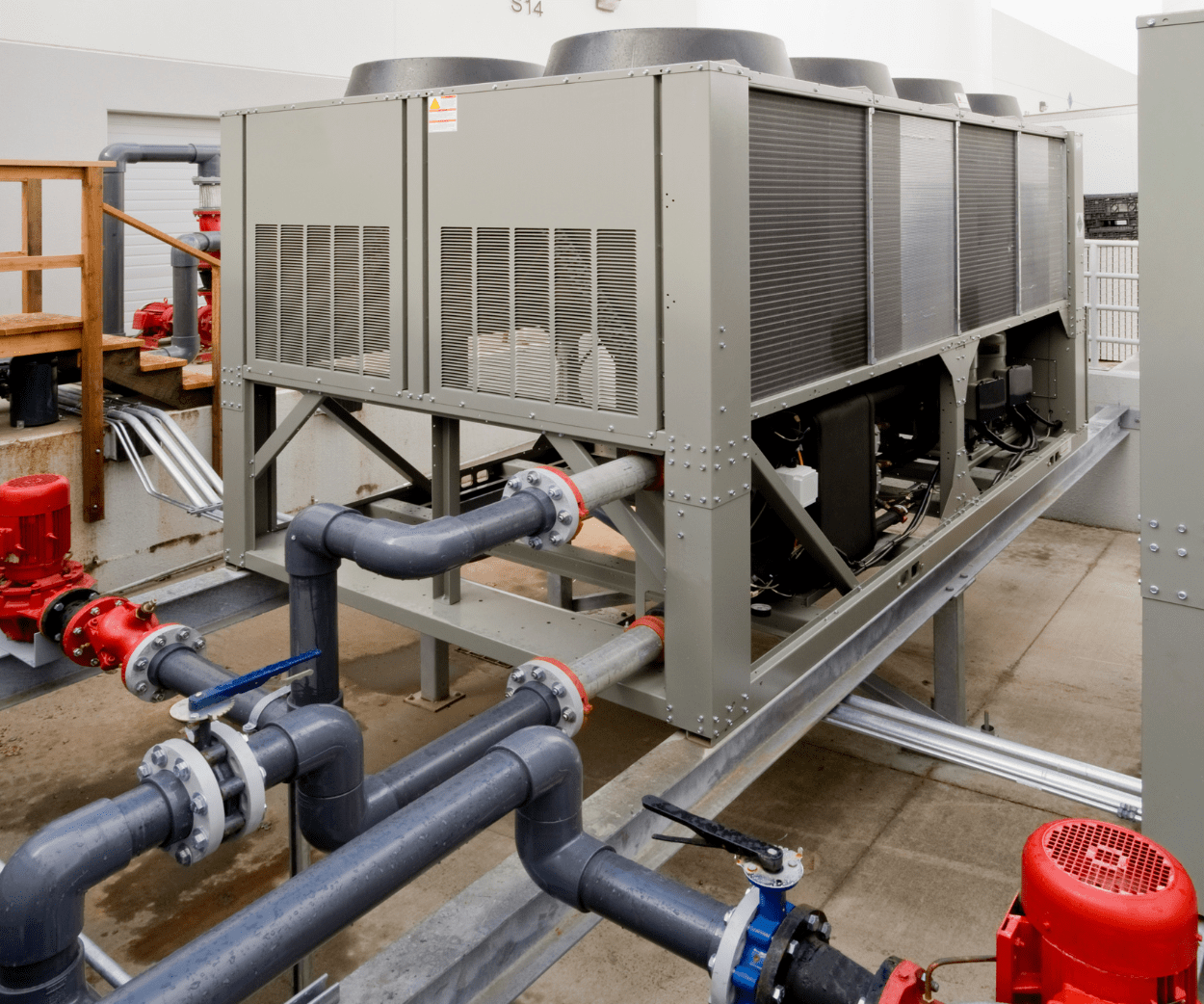

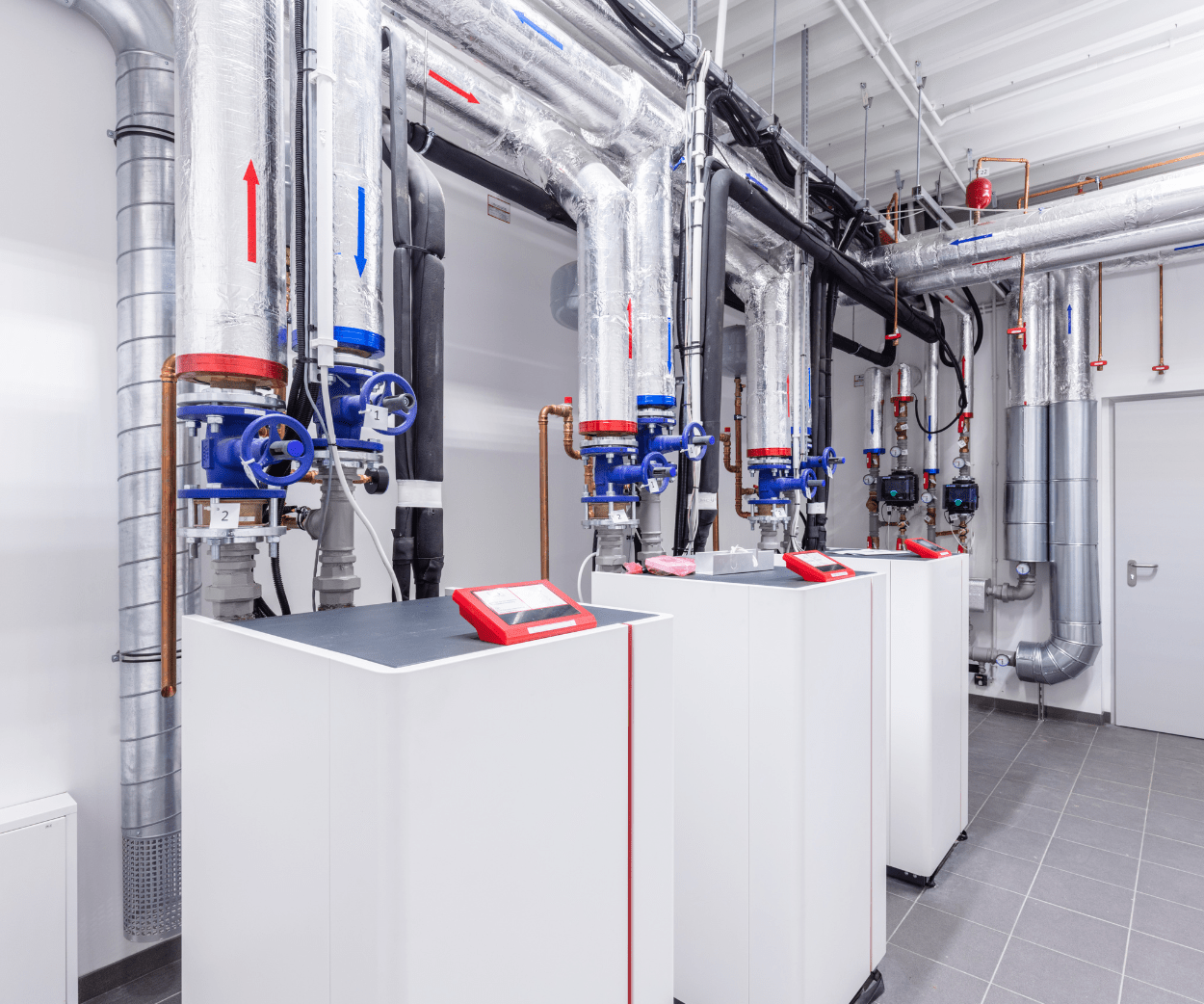

Versatile Application: It’s compatible with any closed-loop hydronic system, making it suitable for a wide range of applications, including chillers, heat pumps, and energy recovery units.

Longevity and Minimal Maintenance: Maxwell™ offers a useful life of 10+ years with minimal maintenance requirements, ensuring long-term reliability and sustainability.

Versatile Application: It’s compatible with any closed-loop hydronic system, making it suitable for a wide range of applications, including chillers, heat pumps, and energy recovery units.

Longevity and Minimal Maintenance: Maxwell offers a useful life of 10+ years with minimal maintenance requirements, ensuring long-term reliability and sustainability.

How does it work?

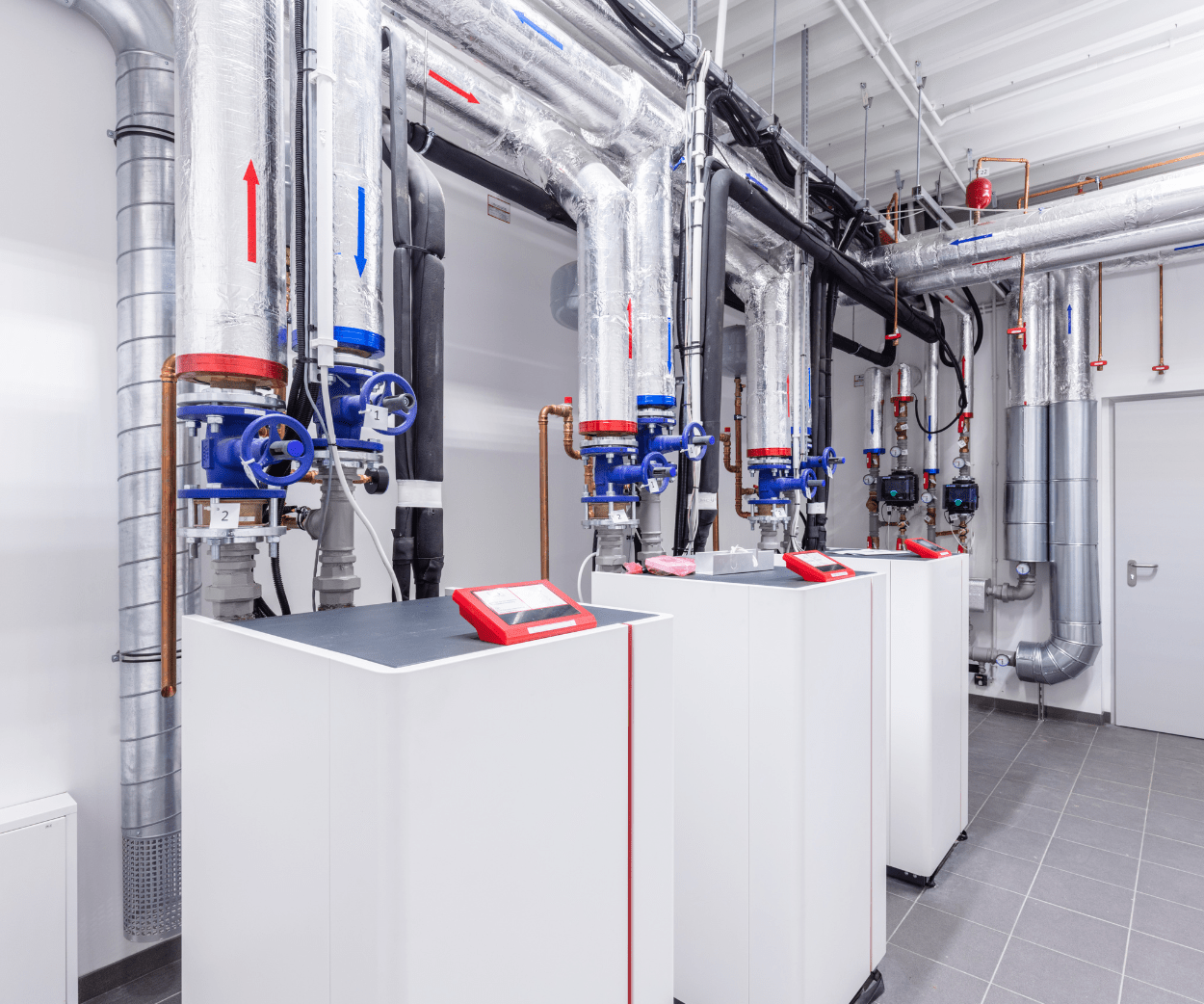

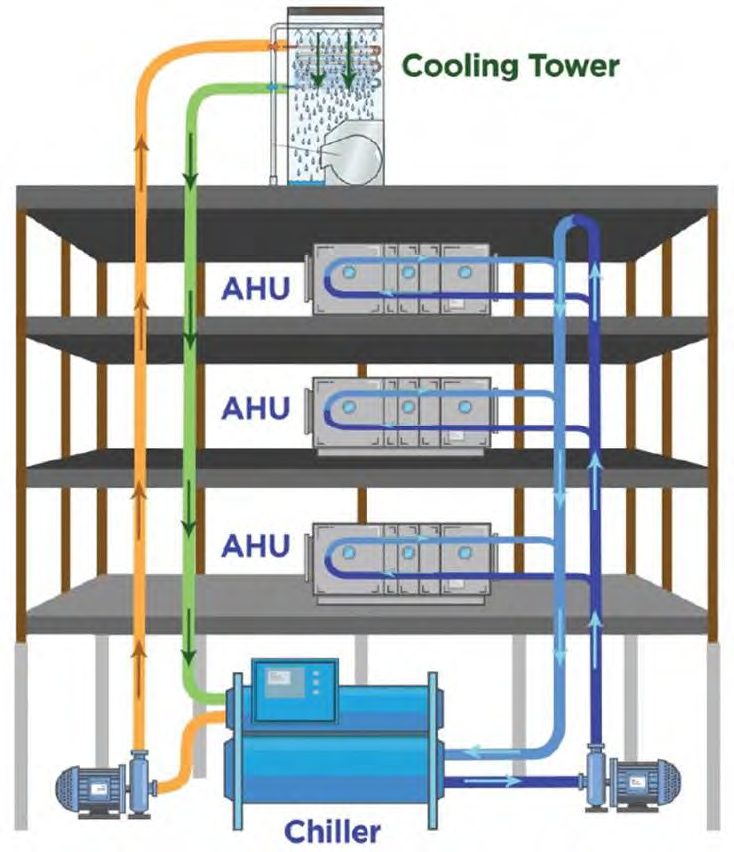

Water (or a water/glycol mix) is circulated from the chiller in a closed evaporator loop (blue) to air handling units (AHU). Maxwell™ can also be used in a closed condenser circuit with a closed cooling tower.

Maxwell™ increases the transfer of heat in the chiller evaporation cycle, reducing compressor “lift” or work.

Maxwell™ also increases thermal energy transfer in the AHU coils, satisfying room set points more quickly, requiring less chilled water and reducing pump energy.

How does it work?

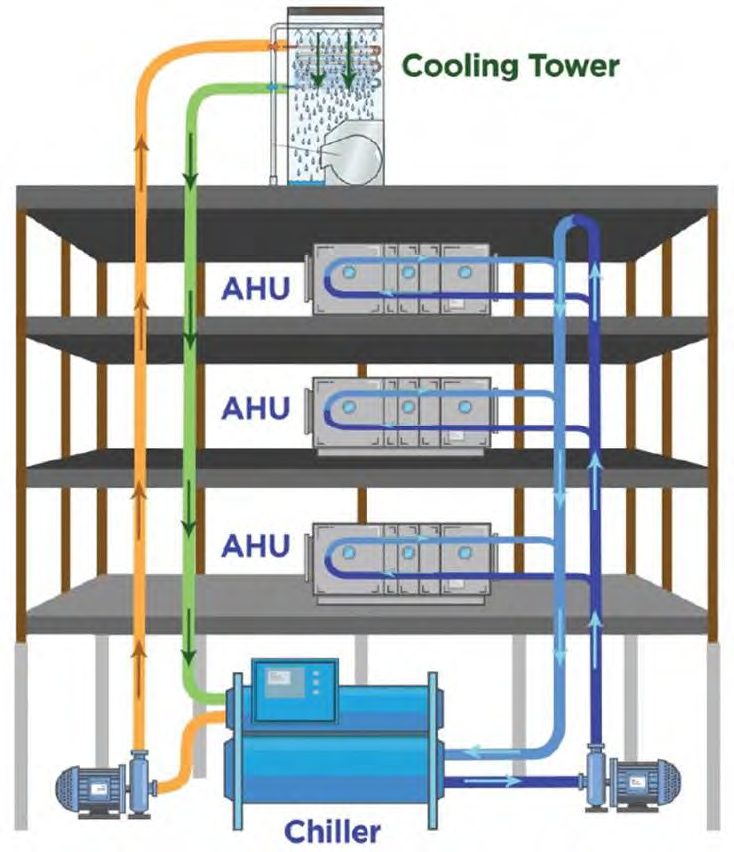

Water (or a water/glycol mix) is circulated from the chiller in a closed evaporator loop (blue) to air handling units (AHU). Maxwell™ can also be used in a closed condenser circuit with a closed cooling tower.

Maxwell™ increases the transfer of heat in the chiller evaporation cycle, reducing compressor “lift” or work.

Maxwell™ also increases thermal energy transfer in the AHU coils, satisfying room set points more quickly, requiring less chilled water and reducing pump energy.

Case Studies: Performance Results

- Single air-to-water rooftop heat pumps servers individual fan coils throughout a 10,000 square foot office building.

- Maxwell™ was added to the fluid loop to improve the heat pump’s Coefficient of Performance (COP) and its Energy consumption.

- Maxwell™ also increased the heat transfer at the zone fan coil units, allowing thermostats to reach set points more quickly.

- Twin Carrier air-cooled chillers serve individual fan coil units throughout a 10,000 sq foot mixed-use building

- Maxwell™ was added to the fluid loop to improve the heat pump’s Coefficient of Performance (COP) and system’s Energy Efficiency (EE) which directly correlates to a reduction in energy consumption.

- Maxwell™ also increased the heat transfer rate in the fan coil units, allowing thermostats to reach set points more quickly.

- Two energy recovery units and multiple air handling units provide 100% outside air to several laboratories, operating 124/7/365 in two separate buildings

- Maxwell™ was added to the runaround loop to increase heat transfer at the recovery coils at the exhaust dans and air handling units. The improvement in heat transfer allowed for a lower fluid flow rate, reducing both the circulating pump power and annual energy consumption by 10%.

Contact Details

Office: [email protected] | +44(0)1142 821240

Director: Adrian Reynolds | [email protected] | +44(0)7857126072

Sales: Denny Braggins | [email protected] | +44(0)7788692342